Introduction and our story

LEARN ABOUT OUR COMPANY

Overview

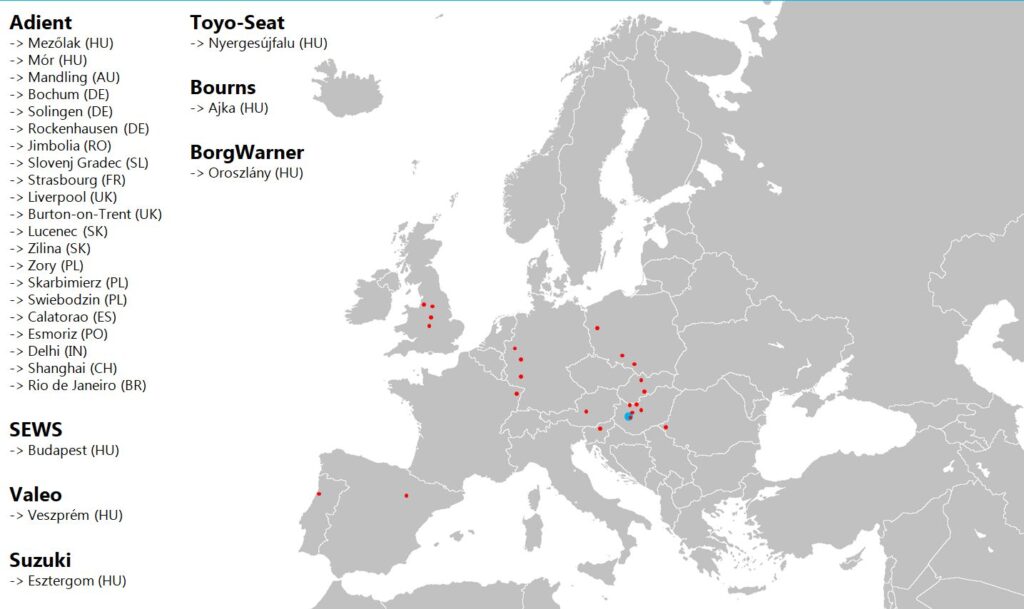

Primarily known as a supplier to the automotive industry. Its activities are based on two main profiles: the production of plastic parts for automotive applications and electromechanical assembly. 95% of the turnover comes from automotive supply, our supplier status: ranging from TIER 1 to TIER 3.

Our activities are based on the following technologies:

- Plastic injection moulding

- Assembly

- Quick press

- Tampo printing

- Laser engraving

Our services range from multi-stage complex assembly production to component manufacturing and custom contract manufacturing.

Our main core activities include plastic injection moulding and fine mechanical manual and semi-automatic assembly, in addition to which we also have tampo printing machines, laser component marking and a quick pressing workshop. We are constantly expanding our technological possibilities and, if necessary, we combine them with sister companies (Ajkai Elektronika, IK Metál Kft., Vart-Speciál Kft., IK Szereléstechnika Kft.) in close cooperation, thus satisfying the highest standard of customer requirements. Our manufacturing base in Ajka is located within a 6-hectare site at Gyár utca 35, where we use ~10,000 m² to serve our partners during the 2022 financial year.

WE HAVE BEEN IN THE HUNGARIAN PLASTIC INJECTION MOULDING BUSINESS SINCE 1962

Our Story

FOUNDATION

THE COMPANY WAS FOUNDED IN AJKÁN UNDER THE NAME VIDEOTON

primarily for the production of radios and TVs. From the end of the 1970s onwards, the manufacture of military radios became a dominant feature.

1962

PRIVATISATION

AFTER PRIVATISATION: KVATTRO RT.

Official partner of Hungarian Suzuki

1992

TRANSFORMATION

100% HUNGARIAN-OWNED INSTRUMENT ENGINEERING HOLDING

buys the company and the Ajkai Elektronikai Kft. is established.

1996

NEW COMPANY FORMED

AE-PLASZTIK KFT.

An important milestone, AE-Plasztik Kft. is established by succession separation from Division II.

2008

FROM LIMITED LIABILITY COMPANY TO PRIVATE LIMITED COMPANY

AE-PLASZTIK KFT. BECOMES AE-PLASZTIK ZRT.

2016

ECONOMIC DEVELOPMENT

TURNOVER OF EUR 17.6 MILLION IS ACHIEVED

an increase of EUR 10 million in 10 years

2017

TECHNOLOGICAL DEVELOPMENT

THE FIRST 900-TONNE INJECTION MOULDING MACHINE ARRIVES

2021

our vision

CONTINUOUS EXPANSION OF PRODUCT PORTFOLIO, IMPROVEMENT OF EFFICIENCY

and by producing higher value-added complex products, we want to become a leading player in the industry!

2022 - 2025

NUMBERS AND DATA

Important information

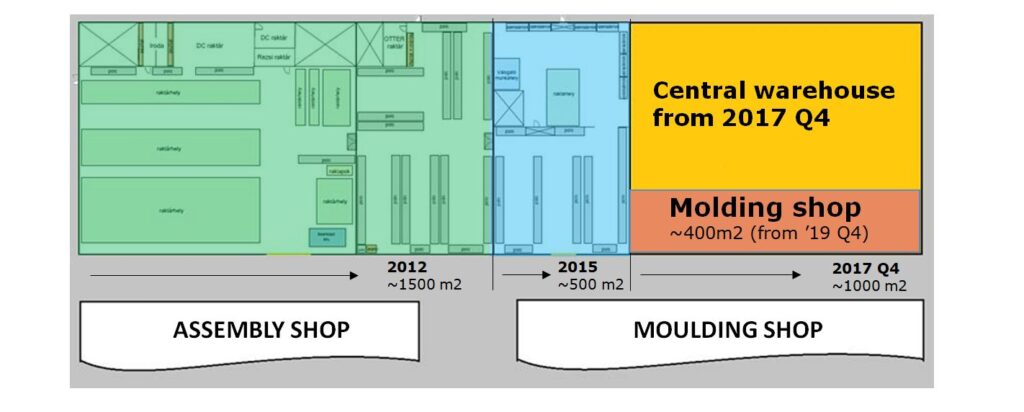

Manufacturing and warehousing on 10,000 m2

Our services range from multi-stage complex assembly production to component manufacturing and custom contract manufacturing.

Our warehouse capacity has improved significantly over the last few years. AEP allocated ~400 m2 for a new injection moulding workshop from Q4 2019. This area houses 7 new injection moulding machines, including 2 new Engel vertical machines and a new 900t Engel machine.